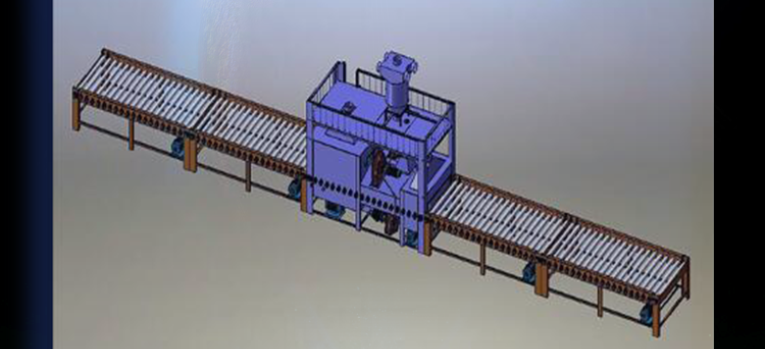

Steel plate, profile, section, H beam shot blasting machine belong to the roller type shot blasting machine ,and mainly used to de-stress and surface de-rust the steel structures,such as Large-scale H steel,etc.In the construction and bridge professions. We can design different size of shot blasting machine for H beam and other structure steel according to customer's demand.

![]()

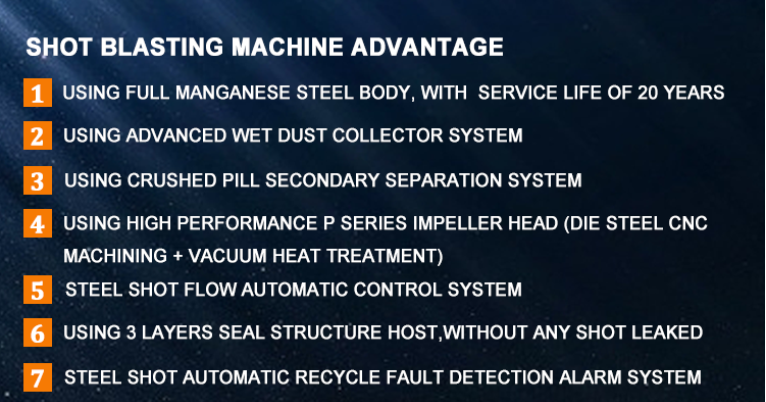

| Shot Blast Machine For Castings Technology Data | |||

| Model | TOKO-1535P11-8 | ||

| TOKO-1535P11-8E | TOKO-1535P11-8H | ||

| NO. | Technology Data | Economical | High Quality |

| 1 | Application |

All Kinds Of Proximate Matter Steel Plate/Round Steel Etc. |

|

| 2 | Machine Size:L*W*H | 38000mm*5000mm*7100mm | |

| 3 | Parts Size:L*W*H | 15000mm*1500mm*1000mm | |

| 4 | Loading Weight Of 1 Roller | 500kgs | |

| 5 | Cleaning Speed(m/min) | 0.5¡ª4 | |

| 6 | Roller Feeding Speed | 0.5¡ª4.5m/min(Frequency Converter Control) | |

| 7 | Dust Emision(mg/m³) | ¡Ü50 | ¡Ü30 |

| 8 | Noise(db) | ¡Ü85 | ¡Ü80 |

| 9 | Total Power(kw) | 158 | 146.5 |

| 10 | Air Loss(m³/min) | 0.5 | |

| NO. | Configuration | Economical | High Quality |

| 2 |

Full Manganese Steel Shot Blasting Room |

YES | YES |

| 3 |

Steel Shot Automatic Recycle System Fault Detection Alarm |

YES | YES |

| 4 | Chain+Roller Transportation | YES | NO |

| 5 | DC-24 Cartridge Filter | YES | YES |

| 6 | Q034-11kw Impeller Head | YES | NO |

| 7 | P11 Impeller Head | NO | YES |

| 8 |

Sepless Speed Change Loading And Unloading System |

YES | YES |

| 9 | Steel Shot Flow Semi-Automatic Control System | YES | NO |

| 10 |

Steel Shot Flow Automatic Control System |

NO | YES |

| 11 |

Impeller Head Frequency Converter Control |

NO | YES |

| 12 | Electrical Cabinet Air Condition | NO | YES |

| 13 | Tooling Customization | For Choose | For Choose |

| 14 | Storage Silo Alarm System | NO | YES |

| 15 | Maintenance Tool (1 Set) | YES | YES |

| 16 | Spare Parts | For Choose | For Choose |

|

|

|

|

|

|

|

|

|

|

Notice :

According to your requirements,the most suitable machines will be designed for your workpieces please indicate the folloing details.

1.what kind of workpiece will you clean ?

2.The workpiece size,length ,width and height of maximum workpiece?

3.How many workpiecs do you want to clean per day ?

Based on this question,the detailed technical proposals will be sent to you for reference

![]()

1.Production time is normally needs 30~50 days.

2.Installation and commissioning time: 10~15 days.

3.Installation and commissioning issue: will send 2-3 technicians to help with machine installation and allowance for our engineers,customer pays for their tickets,hotel and diet Salary is USD

85/day per person.4.Warranty time of machine: 12 months from date of commissioning completion,but no more than 18 months from date of delivery.

5.Payment term: 30% as down payment,70% balance at sight and against B/L copy before delivery.

6.TOKO supply full English documents,including general installation drawing,pit design drawing, manual book, electric wiring diagram,electric manual book and maintenance book ,etc

¡¡

|

|

|

|

For more technology specifications and drawing and offer, please contact with us via info@tokoc.com, our professional engineers work team will provide you service of made-to-order in 24 hours.