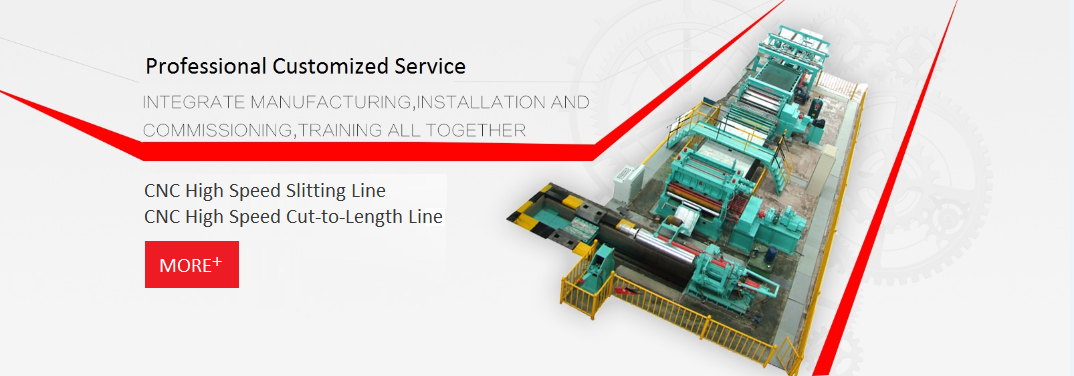

CNC High Speed Cut to Length Line The metal steel coil cut to length line can do uncoiling, straightening, gauging, cross-cutting to length and stacking work. It mainly includes uncoiler, straightener, gauge, shearer, conveyor,stacker, hydraulic system, pneumatic system and electrical system, etc. The line can make sure of accurate feeding and shearing. It can be widely used in cold or hot rolled carbon steel, tinplate, stainless steel and all e other kinds of metal materials with surface coating.

The cut to length line is controlled by PLC system. The information of length, shearing numbers and speed can be input to the PLC systems via HMI(Human Machine Interface) touch screen. When the needed shearing quantity is reached the line can stop automatically. The line speed can be adjusted, It has a gauge with high precision, and whole line can work automatically and operate easily, smooth plates can be made.

![]()

|

Model No. |

Thickness |

Width |

Coil Weight |

Cutting Length Range(mm) |

Stacking Length Range(mm) |

Slitting Speed (2000mm/min) |

Cutting Length Precision(mm) |

Roll Dia. (mm)

|

|

0.15-0.8x1500 |

0.15-0.8mm |

600-1500mm |

10T |

100~99999 |

300~5000 |

40PCs |

±0.3 |

Ф75 |

|

0.20-2.0x1600 |

0.20-2.0mm |

600-1600mm |

10T |

100~99999 |

300~5000 |

40PCs |

±0.3 |

Ф85 |

|

0.30-3.0x1800 |

0.30-3.0mm |

600-1500mm |

20T |

100~99999 |

300~5000 |

40PCs |

±0.5 |

Ф85 |

|

0.50-4.0x1800 |

0.50-4.0mm |

800-1800mm |

20T |

100~99999 |

300~5000 |

40PCs |

±0.5 |

Ф100 |

|

|

|

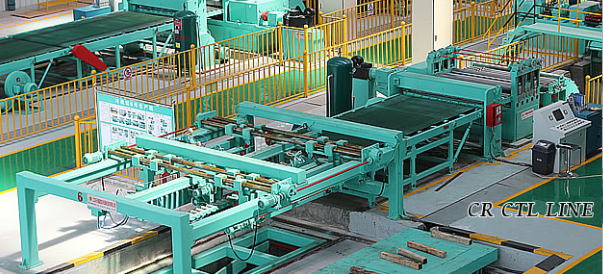

HR Cut to Length Line is used for HR coil(0.5mm-28mm) withdifferent specifications, through uncoiling-leveling-cut to length to flattenedplate as needed length.

This line is composed of coil car, double supportuncoiler, hydraulic pressing and guiding, shovel head, pre-leveler, finishleveler, cut to length machine, stacker, accompany electric control system,hydraulic system, etc. as well as pendulum middle plate, steering device. Watch Slitting Line working Video online at youku

|

|

|

Model No. |

Thickness |

Width |

Coil Weight |

Cutting Length Range(mm) |

Leveler Roll Number |

Cutting Length Precision(mm) |

Roll Dia. (mm)

|

|

3.0 x 1600 |

0.5~3.0mm |

1500mm |

15T |

500-4000 |

15 |

±0.5 |

Ф100 |

|

6.0 x 1600 |

1.0~6.0mm |

1600mm |

15T |

1000-6000 |

15 |

±0.5 |

Ф140 |

|

8.0 x 2000 |

2.0~8.0mm |

2000mm |

20T |

1000-8000 |

13 |

±0.5 |

Ф155 |

|

10 x 2200 |

2.0~10mm |

2200mm |

30T |

1000-10000 |

13 |

±1.0 |

Ф200 |

|

16 x2200 |

4.0~16mm |

2200mm |

30T |

1000-12000 |

11 |

±1.0 |

Ф230 |

|

20 x 2500 |

6.0~20mm |

2500mm |

30T |

1000-12000 |

9 |

±1.0 |

Ф260 |

|

25 x 2500 |

8.0~25mm |

2500mm |

30T |

1000-12000 |

9 |

±1.0 |

Ф300 |

|

|

|

|

![]()

1.Production time is normally needs 50~90 days.

2.Installation and commissioning time: 20~30 days.

3.Installation and commissioning issue: will send 2-3 technicians to help with machine installation and allowance for our engineers,customer pays for their tickets,hotel and diet Salary is USD

85/day per person.4.Warranty time of machine: 12 months from date of commissioning completion,but no more than 18 months from date of delivery.

5.Payment term: 30% as down payment,70% balance at sight and against B/L copy before delivery.

6.TOKO supply full English documents,including general installation drawing,pit design drawing, manual book, electric wiring diagram,electric manual book and maintenance book ,etc

TOKO Group'S Machinery Business Including: CNC high Speed Slitting Line, CNC High Speed Cut to Length Line, CNC Hydraulic Plate Shearing(Cutting)machine, CNC Hydraulic Press Brake (Bending) Machine, Shot blast Cleaning Machine, CO2 Welding Machine, MIG/TIG Welding Machine, ARC Welding Machine etc, Most of our machines are separately exported to Belgium, Russia, Turkey, India, Pakistan, Egypt, Iran, Jordan, Poland, Ethiopia, Indonesia, Vietnam, Burma, Australia, Brazil, Mexico, Venezuela, Africa etc. Our professional engineers work team will provide you service and solution in 24 hours.