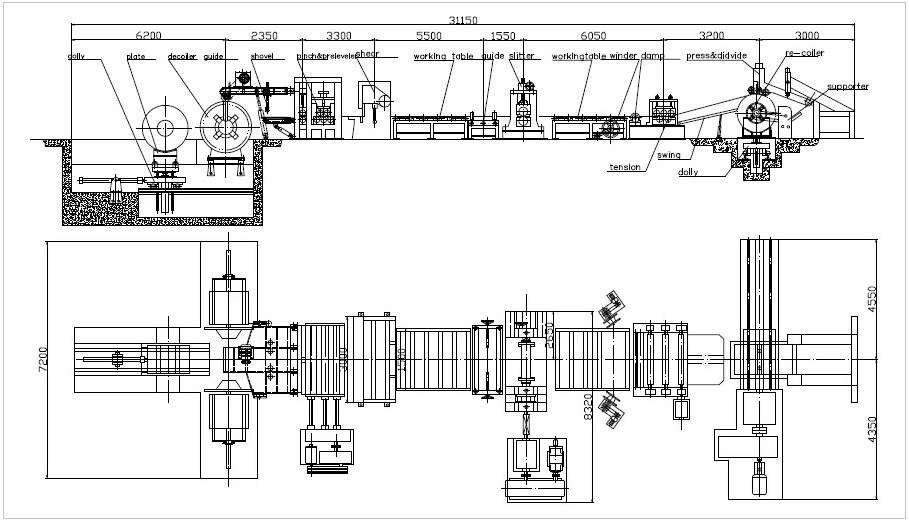

HR, CR Slitting Line is auto line with operate easily and high productivity, raw material is hot steel ,stainlesssteel,aluminum ,pickle steel etc. It is mainly composed ofun-coiler, feeder, slitter and re-coiler. Its function is to slit a wide coilto stated width strips coil along with the length direction which can be usedfor construction product like wall and roof ,some door & window frame etc , At same time, changing different material blade can slit various metalcoils. Watch Slitting Line working Video online at youku

| Slitting Line details | ||

| Material: AL,GI, HR, SS, CR, Copper etc. | Thickness:0.2-2.0mm (max is 12mm) |

|

| Coil ID: 508 or 610 or 760 mm | Coil max width: 200~~2000MM | |

| Coil max weight: 8T~30 T | Application: for pipe or just processing | |

| Monthly production: 500T~4000T | Max Strips you want to slit: 2~40 PCS | |

| Speed: 15~200m/min | Slitting Tolerance:±0.5mm | |

| Machine Components | ||

| 1, coil car | 2, decoiler | |

| 3, two pinch, shear | 4, loop pit | |

| 5, manual/electric side guider | 6, slitter | |

| 7, edge coil rewinder | 8, loop pit | |

| 9, tension station | 10, recoiler | |

| 11, push device | 12, coil car | |

| 13, hydraulic system | 14, electric system | |

|

Model No. |

Thickness |

Width |

Coil Weight |

Finish Weidth |

Slitting Strips |

Slitting Speed |

Recoiler Dia |

Shaft Dia. |

|

3.0×1600 |

0.25-3.0mm |

600-1800mm |

25T |

≥30mm |

≤13 |

0-180m/min |

Ф508 |

Ф240 |

|

4.0×1600 |

0.5-4.0mm |

900-1600mm |

30T |

≥60mm |

≤13 |

0-120m/min |

Ф508 |

Ф240 |

|

6.0×1600 |

1.0-6.0mm |

900-1600mm |

30T |

≥60mm |

≤10 |

0-80m/min |

Ф610 |

Ф260 |

|

8.0×2000 |

2.0-8.0mm |

900-2000mm |

35T |

≥70mm |

≤6 |

0-50m/min |

Ф610 |

Ф300 |

|

10×2200 |

3.0-10mm |

900-2200mm |

35T |

≥80mm |

≤5 |

0-50m/min |

Ф760 |

Ф320 |

|

12×2200 |

3.0-12mm |

900-2200mm |

35T |

≥100mm |

≤5 |

0-50m/min |

Ф760 |

Ф320 |

|

16×2500 |

4.0-16mm |

900-2500mm |

35T |

≥100mm |

≤5 |

0-30m/min |

Ф760 |

Ф400 |

|

20×2500 |

6.0-20mm |

900-2500mm |

35T |

≥100mm |

≤4 |

0-20m/min |

Ф760 |

Ф480 |

|

|

|

|

|

|

CR Slitting Line is auto line with operate easily and high productivity ,raw material is cold steel ,stainlesssteel,aluminum ,pickle steel etc .It is mainly composed ofun-coiler, feeder, slitter and re-coiler. Its function is to slit a wide coilto stated width strips coil along with the length direction which can be usedfor construction product like wall and roof ,some door & window frame etc , At same time, changing different material blade can slit various metalcoils.

|

|

![]()

|

Model No. |

Thickness |

Width |

Coil Weight |

Finish Weidth |

Slitting Strips |

Slitting Speed |

Recoiler Dia |

Shaft Dia. |

|

0.20-2.0x1500 |

0.20-2.0mm |

600-1500mm |

15T |

≥30mm |

≤25 |

≤180m/min |

Ф508 |

Ф220 |

|

0.25-3.0x1600 |

0.25-3.0mm |

600-1600mm |

15T |

≥60mm |

≤25 |

≤180m/min |

Ф508 |

Ф240 |

|

0.30-3.5x1800 |

0.50-3.0mm |

600-1800mm |

20T |

≥60mm |

≤25 |

≤180m/min |

Ф508,Ф610 |

Ф240 |

|

0.50-4.0x1800 |

0.50-4.0mm |

600-2000mm |

25T |

≥70mm |

≤25 |

≤180m/min |

Ф508,Ф610 |

Ф240 |

|

|

|

|

![]()

1.Production time is normally needs 50~90 days.

2.Installation and commissioning time: 20~30 days.

3.Installation and commissioning issue: will send 2-3 technicians to help with machine installation and allowance for our engineers,customer pays for their tickets,hotel and diet Salary is USD 85/day per person.

4.Warranty time of machine: 12 months from date of commissioning completion,but no more than 18 months from date of delivery.

5.Payment term: 30% as down payment,70% balance at sight and against B/L copy before delivery.

6.TOKO supply full English documents,including general installation drawing,pit design drawing, manual book, electric wiring diagram,electric manual book and maintenance book ,etc

For more technology specifications and drawing and offer, please contact with us via info@tokoc.com, our professional engineers work team will provide you service of made-to-order in 24 hours.