What's advantages from TOKO slitting Line?

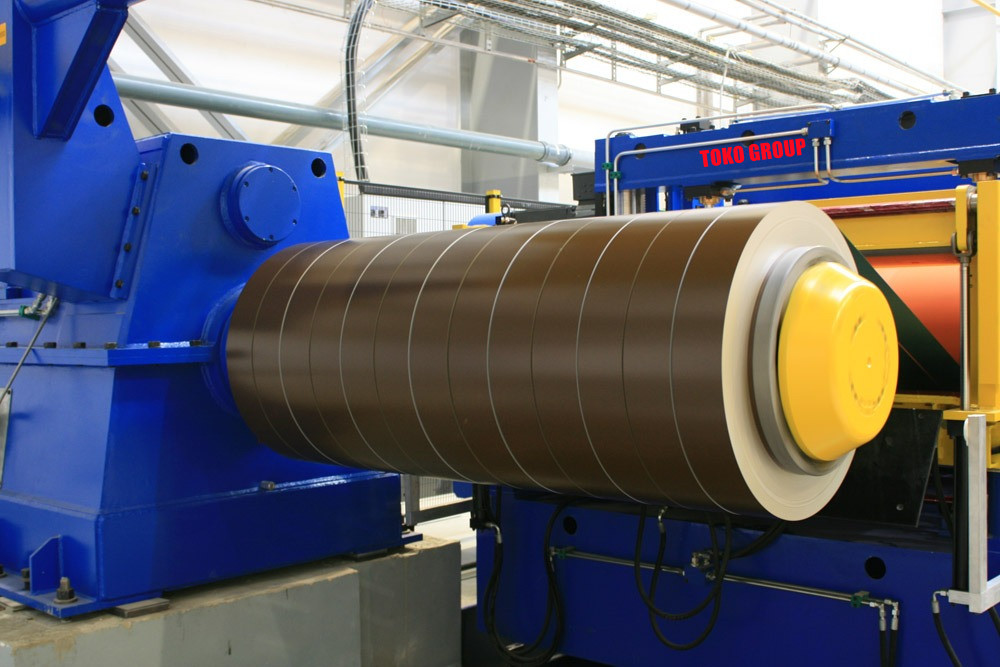

CNC Slitting Line is an advanced industrial machine system designed to process large metal coils (typically steel, aluminum, or stainless steel) into narrower strips with precise widths. Controlled by Computer Numerical Control (CNC) technology, it automates the slitting process for high efficiency, accuracy, and repeatability in metal fabrication. Here’s a detailed description:

Key Components & Functionality

-

✅Decoiler: Holds and feeds the master coil into the system.

-

✅Leveling Unit: Flattens the metal sheet to remove distortions.

-

✅Slitter Head: Equipped with rotary circular knives programmed to make longitudinal cuts.

-

✅Edge Trimming: Removes uneven edges for clean, uniform strips.

-

✅Tension Stand: Maintains consistent material tension during processing.

-

✅Re-coiler: Winds the slit strips into smaller, ready-to-use coils.

-

✅CNC Control Panel: Allows operators to input parameters (width, speed) and monitor real-time adjustments.

Technical Specifications

-

✅Material Thickness: 0.3mm – 6.0mm

-

✅Max Coil Width: Up to 2,000mm

-

✅Line Speed: Up to 300 meters/minute

-

✅Width Tolerance: ±0.1mm

-

✅Applications: Automotive parts, pipe manufacturing, HVAC systems, construction materials, and appliance production.

Advantages

✅ Precision Cutting: CNC-programmable knives ensure exact widths for high-volume orders.

✅ High Efficiency: Automated operation reduces labor costs and minimizes material waste.

✅ Quick Changeover: Digital adjustments enable fast transitions between different strip specifications.

✅ Quality Control: Integrated sensors detect defects, and laser measurement systems ensure dimensional accuracy.

✅ Safety Features: Emergency stops, safety guards, and overload protection.

Why Choose TOKO’s CNC Slitting Line?

TOKO’s systems are ISO 9001-certified and optimized for:

-

✔Smart Manufacturing: IoT-enabled diagnostics for predictive maintenance.

-

✔Customization: Tailored for processing carbon steel, galvanized steel, aluminum, and specialty alloys.

-

✔Cost Savings: Implements TOKO’s C2F (Coil-to-Finished) model for 40% faster delivery and zero-inventory solutions.

Ideal for manufacturers seeking scalable, automated metal processing solutions with zero-defect output.

In summary, the advantages of TOKO's Slitting Line stem from its precision, efficiency, versatility, reliability, ease of use, and the comprehensive support offered by the manufacturer.