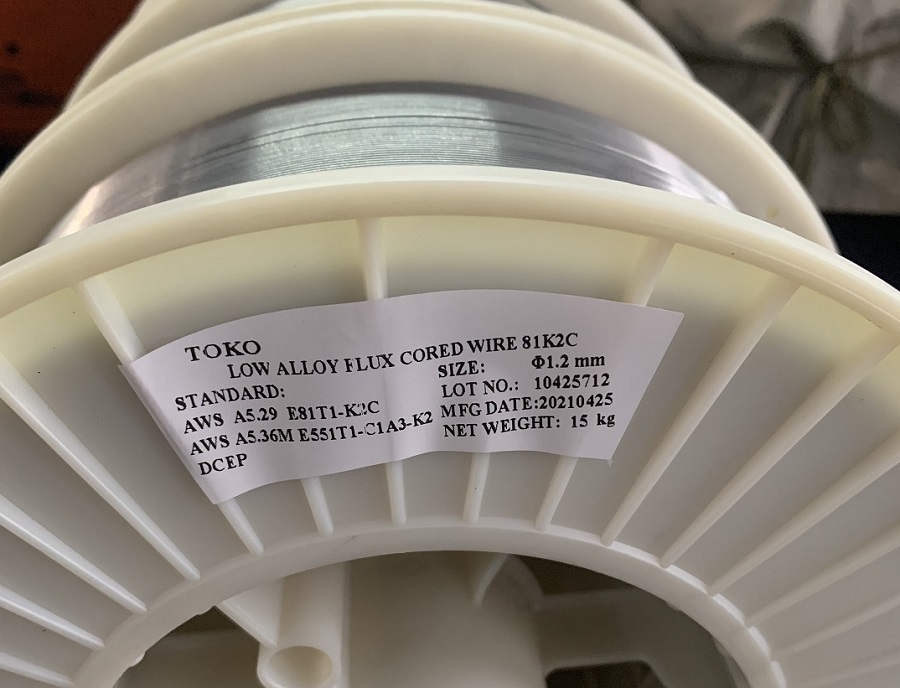

AWS A5.29 E81T1-K2C

It provides excellent usability with stable ARC and efficiency in all-positions of welding. It is suitable for butt or fillet welding of offshore steel structurest, petrochemicals engineering, shipbuilding, pressure vessel, LNG and LPG carriers, and storage tanks, etc.

Flux-cored arc welding (FCAW or FCA) is a semi-automatic or automatic arc welding process. FCAW requires a continuously-fed consumable tubular electrode containing a flux and a constant-voltage or, less commonly, a constant-current welding power supply. An externally supplied shielding gas is sometimes used, but often the flux itself is relied upon to generate the necessary protection from the atmosphere, producing both gaseous protection and liquid slag protecting the weld. The process is widely used in construction because of its high welding speed and portability.

Mechanical

Properties of Welded

Metal

(kgf/mm2)

(kgf/mm2)

Sizes and Current Range

Attentions before of Welding:1. The oil stains and rust on the weldments should be cleared away before welding.2. Shielding gas flow rate: 20-25L/min during welding.3. Designed for welding with 100% CO2.4. Storage : Vacuum packaging less than 12 months, other packaging less than

6 months.

Chemical

Compositions (%)

C

Mn

Si

S

P

Cr

Ni

Mo

Balance

Standard

≤0.15

0.50~1.75

≤0.80

≤0.030

≤0.030

≤0.15

1.0~2.0

≤0.35

---

Test

0.05

1.25

0.20

0.008

0.015

0.02

1.25

0.005

---

Impack Energy

Average

Yield Strength (N/mm)

Tensile Strength

(N/mm2)

Elongation(%)

(J)

Value

(J/℃)

Standard

≥470

550~690

≥19.50

≥47

-40℃

Test

590

650

26.50

70 71 72

70 J

Diameter (MM)

1.2MM

1.6MM

Current (Amp)

Flat

280~300 A

290~310 A

ARC Voltage

Vertical Up/Overhead

240-250 V

240-250 V

TOKO Flux Cored Welding Wire is a reliable and high-performing welding consumable that offers exceptional welding properties, versatility, and cost-effectiveness. Its use can significantly improve the quality and efficiency of welding operations, download AWS E81T1-K2C MTC .

The information contained or otherwise referenced herein is presented only as “typical” without guarantee or warranty, and TOKO Corporation expressly disclaims any liability incurred from any reliance thereon. Typical data and Test results for mechanical properties, deposit or electrode composition and other properties were obtained from a weld produced and tested according to prescribed standards, and should not be assumed to be the expected results in a particular application or weldment. Actual results will vary depending on many factors, including, but not limited to, weld procedure, plate chemistry and temperature, weldment design and fabrication methods. Users are cautioned to confirm by qualification testing, or other appropriate means, the suitability of any welding consumable and procedure before use in the intended application.