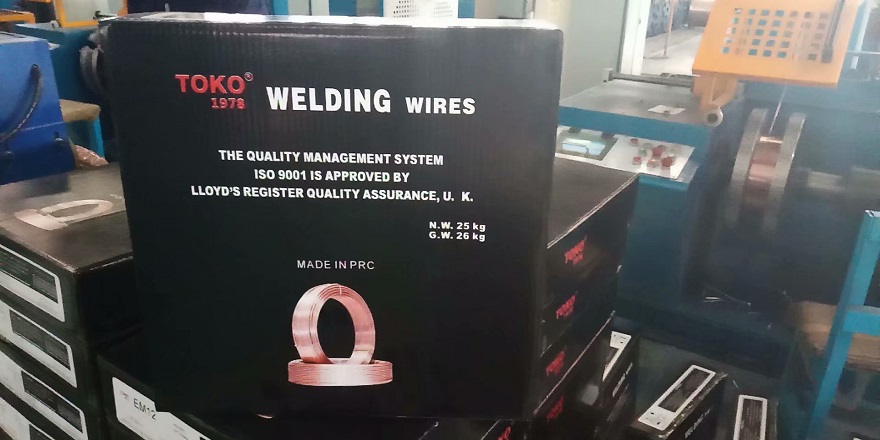

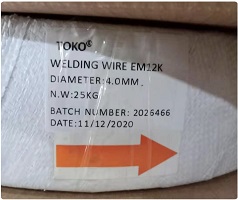

TOKO AWS A5.17 EM12K is a copper-coated carbon-steel solid wire for submerged arc welding wire.EM12K is a versatile, general purpose product suitable for joining a wide range of non-alloyed steels with a wide variety of flux(es). submerged arc welding wire from Grainger in a variety of diameters to fit your submerged arc welding (SAW) applications.

SAW is similar to MIG welding, but the area being welded is covered by a blanket of flux, which helps reduce UV radiation and can provide a higher quality weld.

EM12K Applications: Single and multiple-pass welding using recommended fluxes, non-alloyed and fine-grain steels, general fabrication, structural components, heavy equipment components, railcar frames, wheel fabrication, storage tanks, boilers, pressure vessels, ship panels, pipe double jointing, wind towers

Industries:

General fabrication, heavy equipment, railcar, shipbuilding, structural & bridge fabrication, power generation, oil & gas, offshore

Submerged ARC Welding:

Submerged arc welding (SAW) is a common arc welding process. The process requires a continuously fed consumable solid or tubular (metal cored) electrode.

The molten weld and the arc zone are protected from atmospheric contamination by being "submerged" under a blanket of granular fusible flux consisting of lime, silica, manganese oxide, calcium fluoride, and other compounds.

When molten, the flux becomes conductive, and provides a current path between the electrode and the work. This thick layer of flux completely covers the molten metal thus preventing spatter and sparks as well as suppressing the intense ultraviolet radiation and fumes that are a part of the shielded metal arc welding (SMAW) process.

AWS A5.17

EM12K Chemical

Compositions (%)

AWS A5.17 EM12K Mechanical

Properties

C

Mn

Si

S

P

Cr

Ni

Cu

Balance

0.110

1.020

0.220

0.012

0.010

0.013

0.005

0.008

---

Yield Strength (MPa)

Tensile Strength

(MPa)

Elongation(%)

Akv

(J/℃)

436

532

28

80J / -20℃

The information contained or otherwise referenced herein is presented only as “typical” without guarantee or warranty, and TOKO Corporation expressly disclaims any liability incurred from any reliance thereon. Typical data and Test results for mechanical properties, deposit or electrode composition and other properties were obtained from a weld produced and tested according to prescribed standards, and should not be assumed to be the expected results in a particular application or weldment. Actual results will vary depending on many factors, including, but not limited to, weld procedure, plate chemistry and temperature, weldment design and fabrication methods. Users are cautioned to confirm by qualification testing, or other appropriate means, the suitability of any welding consumable and procedure before use in the intended application.