AWS A5.18 ER70S-6

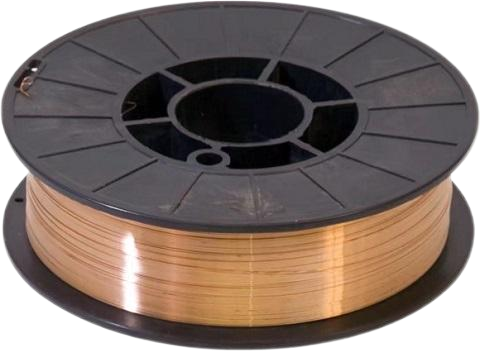

TOKO ER70S-6 MIG welding wire is a copper-coated, low-alloy steel MIG (Metal Inert Gas) welding wire that meets the specifications of AWS A5.18 ER70S-6 and various international standards, including GB/T8110 ER50-6, BS EN ISO14341-A-G423C, and G3Si1. This welding wire is characterized by excellent welding process performance, including stable arc burning, low spatter, beautiful weld bead formation, and low sensitivity to porosity in the weld metal. It can be used for welding a wide range of current settings.

TOKO ER70S-6 MIG welding wire is primarily intended for welding important structures made of shipbuilding steel and low-alloy steel of similar strength grades. It can be applied in the welding of various applications, such as vehicles, bridges, buildings, mechanical structures, as well as for high-speed welding of thin plates and pipes. This welding wire is suitable for welding with carbon dioxide (CO2) or argon-rich shielding gases.

TOKO brand ER70S-6 welding wire is a popular choice for various welding applications due to its superior features and performance. Here are the main features and applications of this welding wire:

TOKO ER70S-6 MIG welding wire is a copper-coated, low-alloy steel MIG (Metal Inert Gas) welding wire that meets the specifications of AWS A5.18 ER70S-6 and various international standards, including GB/T8110 ER50-6, BS EN ISO14341-A-G423C, and G3Si1. This welding wire is characterized by excellent welding process performance, including stable arc burning, low spatter, beautiful weld bead formation, and low sensitivity to porosity in the weld metal. It can be used for welding a wide range of current settings.

TOKO ER70S-6 MIG welding wire is primarily intended for welding important structures made of shipbuilding steel and low-alloy steel of similar strength grades. It can be applied in the welding of various applications, such as vehicles, bridges, buildings, mechanical structures, as well as for high-speed welding of thin plates and pipes. This welding wire is suitable for welding with carbon dioxide (CO2) or argon-rich shielding gases.

TOKO brand ER70S-6 welding wire is a popular choice for various welding applications due to its superior features and performance. Here are the main features and applications of this welding wire:

Main Features:

- Excellent Weldability: TOKO ER70S-6 welding wire is designed to provide smooth and stable welding arcs, resulting in high-quality welds.

- Low Spatter Generation: This welding wire produces minimal spatter during welding, which helps maintain a clean and efficient welding environment.

- Good Mechanical Properties: The welds produced using TOKO ER70S-6 welding wire exhibit good tensile strength, ductility, and impact resistance.

- Versatile Application: This welding wire is suitable for welding in different positions, including horizontal, vertical, and overhead welding.

- Suitability for Various Materials: TOKO ER70S-6 welding wire is primarily used for welding low-carbon and low-alloy steels, but it can also be used for welding medium-strength steels.

- Shipbuilding: TOKO ER70S-6 welding wire is commonly used in shipbuilding, particularly for welding hull structures and other critical components.

- Bridge Construction: Its excellent weldability and mechanical properties make it suitable for welding bridge structures.

- Construction Industry: This welding wire is widely used in the construction industry for welding steel beams, columns, and other structural components.

- Automotive Industry: TOKO ER70S-6 welding wire is also suitable for welding automotive components, such as chassis, frames, and suspension systems.

- Machinery Manufacturing: It can be used for welding various machinery parts and components made of low-carbon and low-alloy steels.

-

AWS A5.18 ER70S-6 Typical Chemical Compositions (%) C Mn Si S P Cr Ni Mo Balance 0.080 1.45 0.85 0.012 0.012 0.020 0.010 0.002 --- AWS A5.18 ER70S-6 Typical Mechanical Properties

Yield Strength (N/mm) Tensile Strength (N/mm2) Elongation(%) Impack Value (J/℃) >430 >540 >25 150/+20℃ 90J / -30℃

|

Available Sizes and recommended Current Ranges |

||||

|---|---|---|---|---|

|

Diameter (MM) |

0.8MM | 1.0MM | 1.2MM | 1.6MM |

|

Current (Amp) |

60~200 | 80~300 | 120~380 | 220~550 |

The information contained or otherwise referenced herein is presented only as “typical” without guarantee or warranty, and TOKO Corporation expressly disclaims any liability incurred from any reliance thereon. Typical data and Test results for mechanical properties, deposit or electrode composition and other properties were obtained from a weld produced and tested according to prescribed standards, and should not be assumed to be the expected results in a particular application or weldment. Actual results will vary depending on many factors, including, but not limited to, weld procedure, plate chemistry and temperature, weldment design and fabrication methods. Users are cautioned to confirm by qualification testing, or other appropriate means, the suitability of any welding consumable and procedure before use in the intended application.