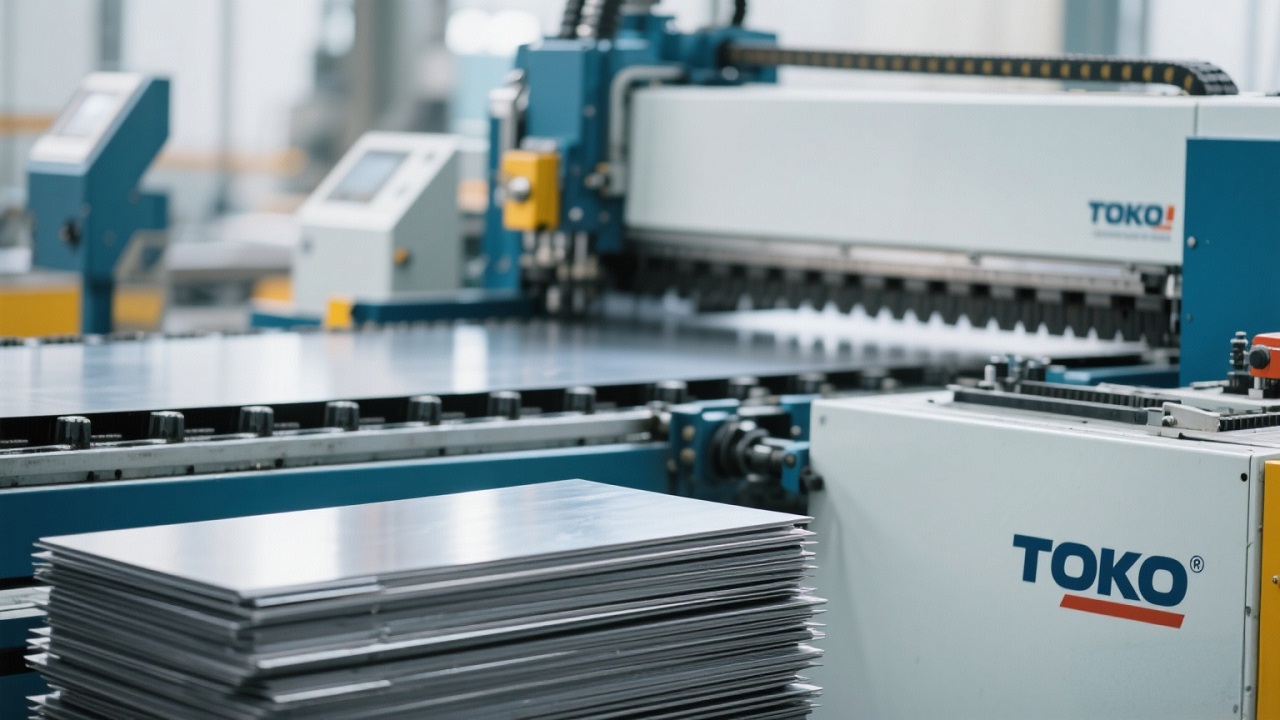

Cut-to-Length Line

Cut-to-Length Line is an integrated machine system that processes metal coils through decoiling, leveling, measuring, shearing, and stacking to produce accurately sized flat sheets efficiently.

Uncoiling

Master coil is securely mounted and fed into the system with precision tension control to prevent material deformation.

Leveling & Measuring

Material passes through precision levelers to remove coil set, then measured for exact cutting length.

Precision Cutting

High-speed hydraulic or pneumatic shears cut material to specified lengths with tolerance within ±0.5mm.

Stacking & Output

Finished sheets are automatically stacked, counted, and prepared for packaging or further processing.