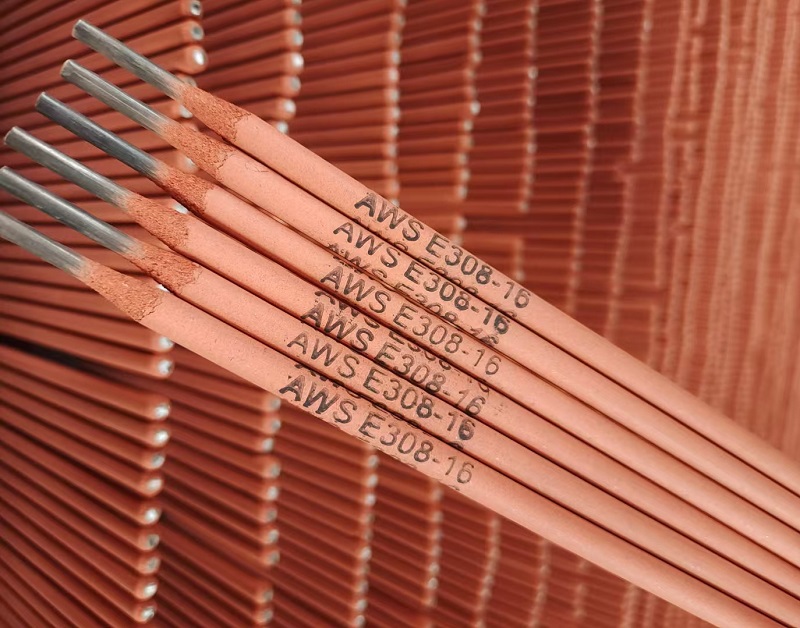

Features of TOKO Brand Welding Electrodes AWS A5.4 E308L

Exceptional performance for 304 and 304L stainless steel welding

Optimal Composition

- Specifically designed for 304 and 304L stainless steel

- Low carbon content prevents carbide precipitation

- Chromium and nickel balanced for corrosion resistance

Superior Corrosion Resistance

- Excellent resistance to intergranular corrosion

- Ideal for welding in corrosive environments

- Suitable for high-temperature applications

Excellent Weldability

- Smooth and stable arc characteristics

- Easy slag removal for clean welds

- Minimal spatter during welding

Mechanical Properties

- High tensile strength and good ductility

- Excellent impact strength at low temperatures

- Consistent performance across all positions

Versatility

- Suitable for all welding positions

- Works with both AC and DC power sources

- Ideal for thin and thick section welding

Quality Assurance

- Manufactured to AWS A5.4 specifications

- Rigorous quality control standards

- Consistent batch-to-batch performance

Technical Specifications

| Property | Value | Standard |

|---|---|---|

| Tensile Strength | 80,000 psi (min) | AWS A5.4 |

| Yield Strength | 60,000 psi (min) | AWS A5.4 |

| Elongation | 35% (min) | AWS A5.4 |

| Chemical Composition | C: 0.04% max, Cr: 19-21%, Ni: 9-11% | AWS A5.4 |

| Welding Positions | All positions | - |

| Current Type | AC or DC (electrode positive) | - |

Common Applications

Chemical Processing Equipment

Food Processing Equipment

Water Treatment Systems

Pharmaceutical Equipment

Heat Exchangers

Architectural Applications

The information contained or otherwise referenced herein is presented only as "typical" without guarantee or warranty, and TOKO Corporation expressly disclaims any liability incurred from any reliance thereon. Typical data and Test results for mechanical properties, deposit or electrode composition and other properties were obtained from a weld produced and tested according to prescribed standards, and should not be assumed to be the expected results in a particular application or weldment. Actual results will vary depending on many factors, including, but not limited to, weld procedure, plate chemistry and temperature, weldment design and fabrication methods. Users are cautioned to confirm by qualification testing, or other appropriate means, the suitability of any welding consumable and procedure before use in the intended application.