Our Steel Products

Cold Rolled Steel

Cold rolled steel is a mill product produced from a hot-rolled pickled coil that has experienced substantial cold reduction at room temperature.

The usual end product is characterized by improved surface, greater uniformity in thickness, and improved mechanical properties as compared with hot-rolled sheet.

- Improved surface quality

- Greater uniformity in thickness

- Enhanced mechanical properties

- Increased strength via strain hardening

Available Types:

Commercial steel, drawing steel, extra deep drawing steel, and extra deep drawing steel plus.

Galvanized Steel

Galvanized steel is steel that has gone through a chemical process to keep it from corroding. The steel gets coated in layers of zinc oxide because this protective metal does not get rusty as easily.

The coating also gives the steel a more durable, hard to scratch finish that many people find attractive.

- Excellent corrosion resistance

- Durable, scratch-resistant finish

- Essential for outdoor, marine applications

- Chemical bonding of zinc to steel

Applications:

Outdoor structures, marine environments, industrial applications, roofing, and construction.

Prepainted Steel (PPGI)

PPGI is pre-painted galvanized iron, also known as pre-coated steel, coil coated steel, color coated steel etc, typically with a hot dip zinc coated steel substrate.

The term is an extension of GI which is a traditional abbreviation for Galvanized Iron.

- Factory pre-painted zinc coated steel

- Available in various colors and finishes

- Superior corrosion resistance

- Enhanced aesthetic appeal

Applications:

Roofing, wall panels, appliances, automotive components, and architectural applications.

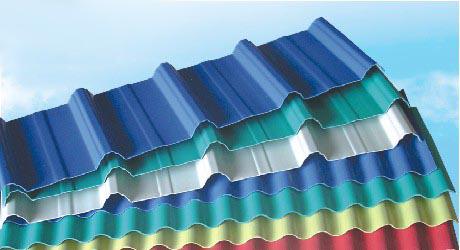

Corrugated Sheet

Corrugated Sheet is made up of color coated sheet, galvanized sheet, and other metal steel sheet after rolling cold bending into a variety of profiles.

- Attractive and innovative appearance

- Rich colors and decorative options

- Light weight with high mechanical properties

- Flexible combination options

Applications:

Industrial and civil buildings, warehouses, steel structure houses, mobile houses, roofs, and interior & exterior decoration.

Tinplate

Tinplate is thin steel sheet with a coating of tin applied either by dipping in molten metal or by electrolytic deposition; almost all tinplate is now produced by the latter process.

Tinplate made by this process is essentially a sandwich in which the central core is strip steel.

- Corrosion-resistant tin coating

- Excellent for food packaging

- High-frequency electric induction coating

- Lustrous protective coat

Applications:

Food and beverage cans, containers, packaging materials, and industrial applications.

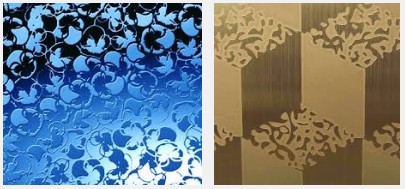

Color Stainless Steel

Customized Color Stainless Steel offers a wide range of both opaque and translucent colors while maintaining the underlying finish texture for enhanced aesthetic appeal.

Stainless steel's superior corrosion resistance makes colored stainless steel an excellent, sustainable materials choice for demanding applications.

- Wide range of color options

- Superior corrosion resistance

- Sustainable material choice

- Texture remains visible

Applications:

Construction, elevator industries, hotel, restaurant and apartment decoration, architectural features.

Steel Pipes

Steel Casing Pipe, also known as encasement pipe, is most commonly used in underground construction to protect utility lines of various types from getting damaged.

Such damage might occur due to the elements of nature or human activity.

- Protection for underground utilities

- Resistant to environmental damage

- Available in various connection types

- Directional pulling capability

Applications:

Underground utility protection, horizontal boring, highway and railroad crossings, underwater installations.

Wire & Wire Mesh

Welded wire mesh, or welded wire fabric, or weldmesh is an electric fusion welded prefabricated joined grid consisting of a series of parallel longitudinal wires with accurate spacing welded to cross wires at the required spacing.

- Prefabricated welded grid

- Available in various sizes and shapes

- Made from low carbon or stainless steel

- Versatile applications

Applications:

Agricultural, industrial, transportation, horticultural, food processing, mining, gardening, machine protection, and decorative applications.