TIG/MIG WELDER

Below is a breakdown of iTOKO TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas) welders and guidance to help you:

1. TIG vs. MIG Welders: Key Differences

-

TIG Welding:

-

MIG Welding:

-

Safety Tips for Welding:

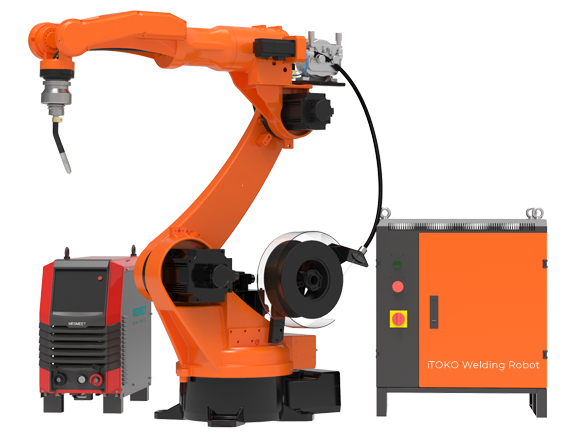

iTOKO ARC robotic welding machine series, range from 5~25kg in payload, it's suitable for a wide range of industrial arc welding applications such as MIG and TIG welding or plasma and laser cutting. Different models are available to meet a variety of demands and all come with a variety of tools to increase their versatility and help make your arc welding processes safer and more efficient.

Cutting Machine

iTOKO plasma cutter uses ionized gas (plasma) to cut through conductive metals like steel, aluminum, and copper. It’s ideal for industrial, automotive, and DIY projects

Key Features to Check

With customer-oriented philosophy, we are dedicated to providing the highest quality products to welding and cutting industry. We strive to provide our customers with the best customer service and support, as well as the most reliable, efficient and economical solutions for their daily welding and cutting needs.