|

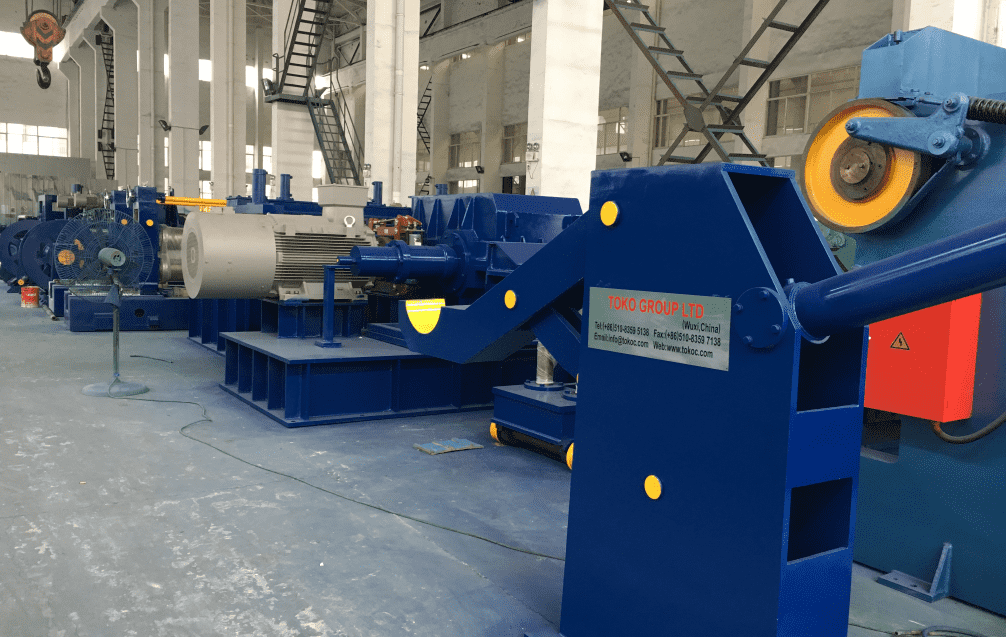

High Speed Slitting Line

TOKO

slitting

line

is

a

processing

line

in

the

metalworking

industry,

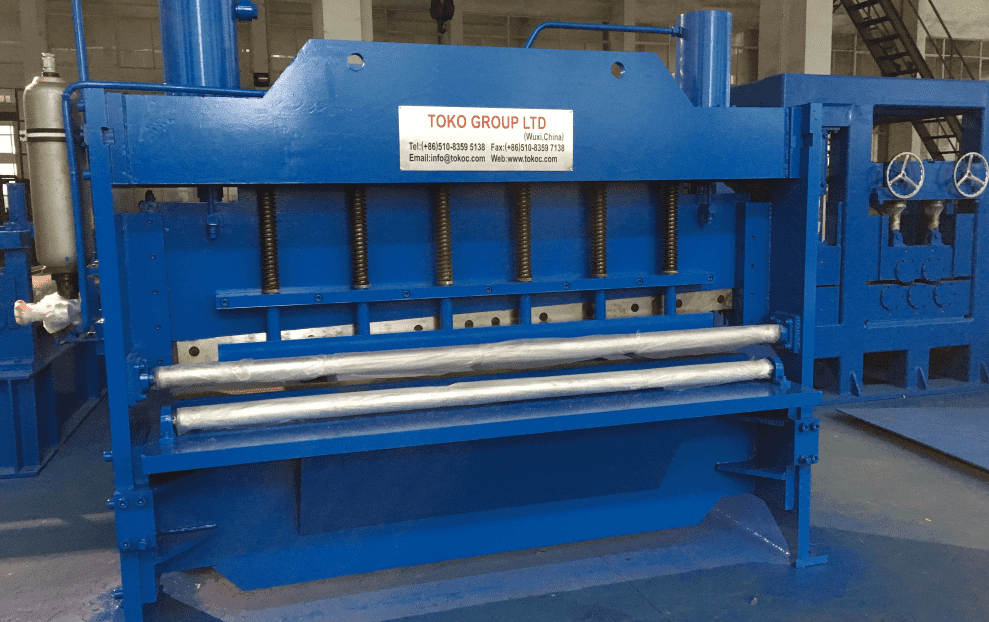

Slitting line will create multiple widths or "mults" from a wider master coil. The mults are made from

predetermined widths. A slitting line is normally consists of three main parts: an uncoiler, slitter, and recoiler. The material is fed from the uncoiler, through

the nip between the two circular cutting wheels (one on top and another underneath), and then re-wound in slit mults on the recoiler..

a). Slitting Line machine is a common machine which

used for metal coil cutting. It is also called longitudinal shearing machine, slitting lines, slitters and cut to length line etc.

a). Slitting Line machine is a common machine which

used for metal coil cutting. It is also called longitudinal shearing machine, slitting lines, slitters and cut to length line etc.

b). Slitting line is used to shear metal material longitudinally and to recoil the fillet. It can be easily operated. This slitting line gives high quality

and precision when cutting material. It utilizes material very efficiently. What's more, the cutting speed is adjustable.

c). The main structures of the slitting machine are composed by uncoiler, head-guiding, slitter and recoiler. The main kinds of applicable material are tinplate, silicon-steel plate, aluminum, copper, stainless steel plate,

galvanized sheet. iTOKO slitting machine is popular in the transformer, the electrical machinery, home appliances, motor vehicles, building material industry, packaging industry, etc.

-

Aluminum

coil (thickness: 0.2mm~3.0mm),

-

Copper

and

brass coil

(thickness: 0.10mm~3.0mm),

-

Stainless

steel

coil

(thickness: 0.10mm~2.0mm),

-

Carbon

steel

HR, CR, GI, PPGI

coil

(thickness: 0.12mm~16.0mm)

,

We provide customized design service for every customer's specicial requirements, watching TOKO Slitting Line, Cut-to-length "CTL" installation and Commissioning video

online at:

YouTube1; YouTube2; YouTube3; YouTube4; YouTube5

and

Video1,

Video2...

Warranty & Service

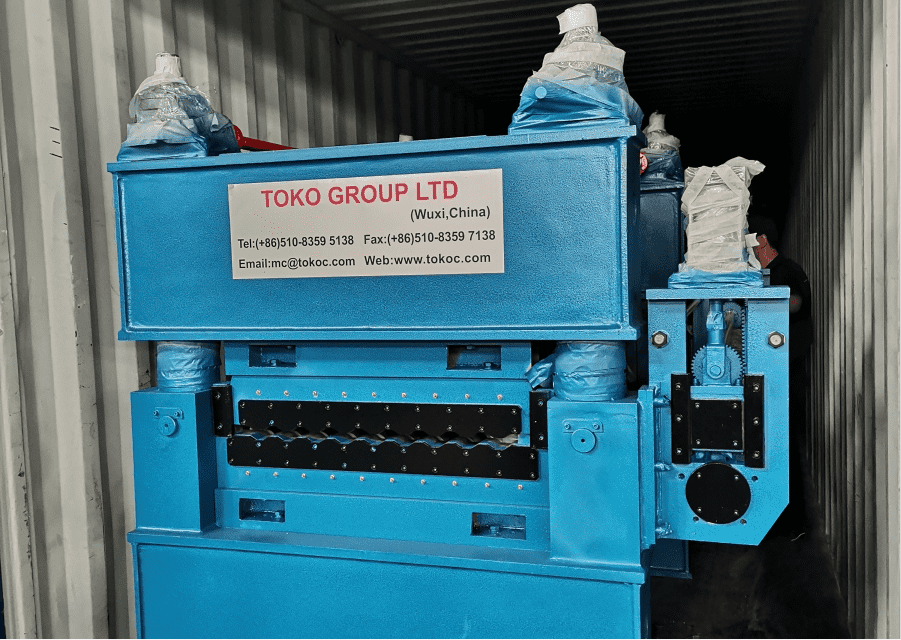

1. Production time depends on its' different specifications

machinery, it normally takes time: 60~90 days .

2. Installation, commissioning

and staff trainning

depends on different machinery, normally takes time: 10~40 days.

3. Installation and commissioning: TOKO will dispatch engineers to buyer's

factory to provide working and service of installation and commissioning,

staff-training. Buyer will pay for the round air-tickets, accommodations and

$100/day allowance for 3 engineers (hydraulic, mechanical and electric engineer)

during the period time of installation and commissioning..

4. Quality Warranty: 12 months from date of commissioning and installation, but no more than 18 months from date of delivery.

5. Payment term: 30% payment in advance by T/T after the contract, and 70%

before the shipment of by IRR L/C at sight issue by world class banks.

As a professional machinery equipments supplier,

TOKO brand machines

have been sold to more than 40 countries and regions over the World. Looking

forwards to establish long-term of partnership with your esteemed company in the coming

future. (view old

site at

iTOKO MACHINE 2016

or from

Audited Supplier).

Any further questions about technology and

solutions, please contact with us via

mc@tokoc.com,

our

engineers will provide you the Customize-Service in 24 hours.

Notes to

Editors

more news about us is coming....

|